What is the difference between compound fertilizer and organic fertilizer?

666Organic fertilizers contain a lot of organic matter that is low in nitrogen, phosphorus, and potassium. It mainly comes from organic materials such as animal and plant residues or human and animal waste. Its main function is to improve soil, provide organic nutrients and improve quality. Compound fertilizer is a kind of chemical fertilizer that contains nitrogen, phosphorus, potassium and other elements at the same time. Generally speaking, compound fertilizers containing two nutrient elements are called binary compound fertilizers, which are inorganic nutrients.

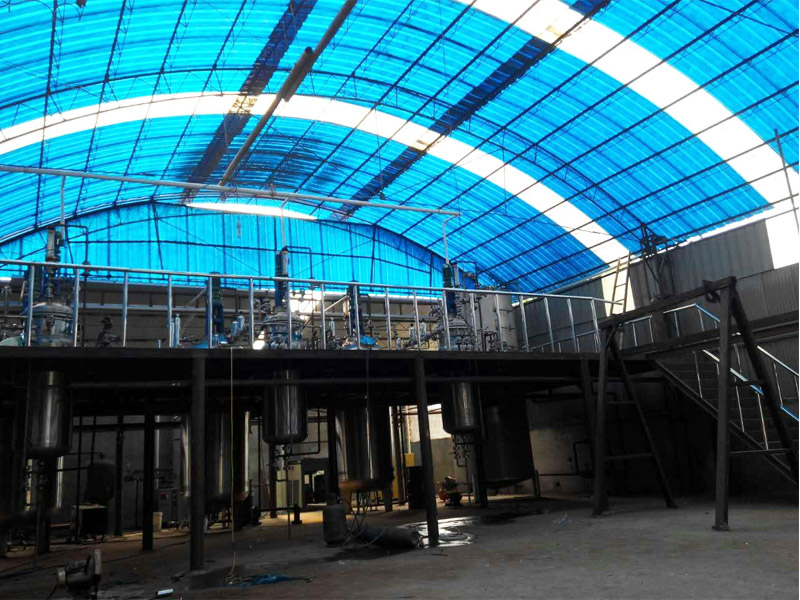

View details Fertilizer equipment_Fertilizer machines_Organic fertilizer equipment

Fertilizer equipment_Fertilizer machines_Organic fertilizer equipment

HelloPlease log in